A Custom Screw Design from Xaloy® Reduces a Medical Packaging Manufacturers Scrap Rate to 1%

Pristine product quality is essential when producing medical products. Maintaining superior melt quality is critical, and running with a non-homogenized or unmelted resin can cause several problems, including poor product quality. The melt quality is affected by multiple factors, including improper screw design, resin sticking in the screw channels, improper barrel temperature profile, inconsistent feed stock, and feed stock bulk density differences. A suboptimal screw design, not tailored to the specific resin and application, is the most common cause.

The Challenge

A medical packaging manufacturer in the eastern United States was experiencing air entrapment in the middle layer of their 3-layer bottle line, causing high scrap rates and undesirable process conditions. They were processing polyamide (PA) with a 45mm 23:1 single-flighted screw. Reaching out to Xaloy, they asked for a solution to ensure satisfactory product quality while allowing them to return to the original process parameters.

THE XALOY APPROACH

Xaloy application engineers performed a comprehensive analysis of the customer-provided process information. This enabled our team to determine what screw design and materials of construction would work best with the customer’s application while correcting their processing issues.

THE XALOY SOLUTION

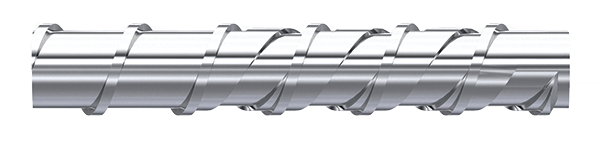

After evaluating the problem, Xaloy engineers recommended an Xaloy® MeltPro™ Barrier Screw with a Pulsar® mixer, one of Xaloy’s best combinations for increased melt homogenization. The Xaloy® MeltPro™ is a high-performance screw that delivers a more homogenized melt than a standard general-purpose screw by separating the melted resins from the solids bed. The Xaloy® MeltPro™ Barrier screw, paired with the Pulsar® mixer increases overall product quality, while allowing a low melt temperature to be maintained.

The Result

After installing Xaloy’s custom-designed screw, the customer reported significant success with the Xaloy® MeltPro™ Barrier with Pulsar® mixer. Their product quality issues were reduced, allowing original process conditions to be used and the scrap rate to decrease from 26% to 1%.

Cost Savings Analysis

Assuming three shifts are worked per day, five days per week, the estimated annual cost of scrap using the original screw was $742,008. However, with the Xaloy screw, the estimated annual cost of scrap is $28,539, resulting in an annual cost savings of $713,469 for the customer.

Process Improvements

- Scrap rate decreased from 26% to 1%

- Process returned to original parameters

Are You Facing

Similar Challenges?

Reach out to our technical engineers to discuss your challenges and to learn how a custom solution from Xaloy can help improve your operations.